Over- speed governor is one of the safety control units of elevator safety protection system. During running, when the car over - speed or even risk to fall while other protection devices do not work,the over-speed governor and safety gear or up-going protective device will generate linkage protection to stop the car. Governor generally be installed inside the elevator machine room or directly installed on the bearing beam, machine roomless governor will be installed on the guide rail or bottom hole on the ground.

Our company currently offers various series of over-speed governor specifications, applicable to different elevator layouts, such as conventional return and non-return machine room governor; machine roomless governor etc. Customers need to learn its function and parameters in accordance with its specification and type. (For details, please study the corresponding type test report)to ensure its performance matching with the elevator actual state.

The elevator safety gear is a device under the control of speed governor, when the elevator over speed its rated speed or in the case of suspension rope breakage or slack, the car stop in emergency and clamp on the guide rail. It provides effective protection to the safe operation of the elevator and generally installed in the car frame or counterweight frame. Safety gear device is composed of two parts: operating mechanism (safety gear linkage mechanism) and braking mechanism (safety clamp).

Our company mainly provides safety gear which divided into the instantaneous type and progressive type. Instantaneous safety gear is applied to elevators ≤0.63 m/s ; progressive safety gear for elevators with rated speed≤2.5m/s. The company offers a variety of installation and specifications, applied in freight elevators and passenger elevators. Customers should choose to match the safety gear according with the structure of the elevator, maximum permit system quality, guide rail specifications, rated speed etc.

Buffer is device to provide a final elevator safety protection generally installed in the elevator shaft bottom pit, located right under the car and counterweight. When the elevator runs upward or downward, it may overrun terminal floor bottom or top because of accidental ineffective braking. Buffer provides absorption to avoid elevator car or counterweight from hitting bottom or top to protect safety for passengers and devices.

According to speed state, buffers can be divided into energy consuming buffer type (oil buffer as representative) and energy storing type (V≤1.0m/s, polyurethane buffer as representative)

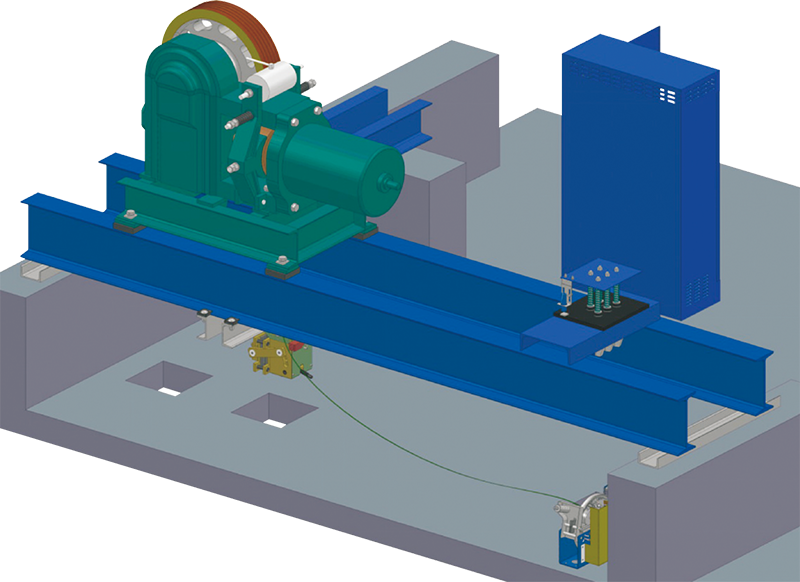

Our OX-250 wire rope brake is used as stopping system in UCMP and as upward overspeed protection device. Measuring car upward overspeed or unintended movement through specialized OX- 240BU and by providing wire rope brake triggering operation through triggering mechanism: the mechanical cable. Achieving restriction over car movement through holding traction wire rope by the moveable and non- moveable clamp plate groups. It'S a protection device with both UCMP and ACOP funtions.

OX-250 wire ripe brake uses two parallel friction boards acting on traction wire rope, meeting two functions: UCMP and ACOP. Its major performance and structure are as follows: installation can be upside down, front or inclined; braking direction adjustable to elevator layout type; stable performace; self-compensating function in wearing to increase the service life of friction boards; short reaction time, flexible and reliable triggering; can realize UCMP through external triggering cable under external power off condition.

Our UCMP OX-250U consists of detection subsystem (OX-240BU OSG, UKZ-01 control power box) and stopping subsystem . (OX-250 wire rope brake device). It uses UKZ-01 control power box to detect car door open or closing signal and provide the signal to OX-240BU OSG in time. The OSG then effectively mark or unmark car position according to car door open or closing state. When the elevator over speed upward or unintendedly moved under the open door state, the OSG OX- 240BU will decide and output triggering signals through the mechanical cable which connected with OX-250 wire rope brake device. Finally the stopping subsystem (OX-250 wire rope brake device) realizes car movement control through traction wire rope. This car unintended movement protection device combined the two functions of UCMP (unintended car movement protection) and ACOP (ascending over- speed protection).

Guide shoe is a sliding guide device between the elevator guide rail and the car or counterweight. It can stabilize the car or counterweight onto the guide rail, allow them to move only upward and downward to prevent any deviation or swing during running. Oil cup can be installed on the upper part of guide shoe to reduce friction between guide shoe lining and guide rail.

Elevator guide shoe consists of the shoe lining, guide shoe, guide shoe base, etc, can be divided into rolling guide shoe and sliding guide shoe series. Sliding guide shoe can be divided into fixed sliding guide shoe and elastic sliding guide shoe, generally applicable to medium-high speed elevator.

Installation of guide shoe needs to meet the following requirements:

A. upper and lower guide shoe should be in the same vertical line, do not allow the skew, partial torsion, ensure upper and lower jaw guide shoe and security center three perfectly aligned;

B. stationary guide shoe is mainly used for transfer, two side clearance should be consistent, lining and the rail top clearance should be 0.5~2 mm.

Keep the speed limiting wire rope tensified to ensure that the wire rope rotates in line with the rotation of the rope wheel and that the speed limiter can provide the necessary brake lift

Company product the other elevator parts: oil can,inspection box, damping pad